When discussing the largest greenhouse gas (GHG) emitter in the food industry, many people immediately think of meat. It is true that meat and dairy production contribute to approximately 15% of global GHG emissions. However, according to the United Nations, there is another significant but lesser-known contributor to climate change in the food and beverage industry, accounting for 4% of global GHG emissions—the cold chain. We are in desperate need of making the food cold chain sustainable.

In recent times, the United Nations has highlighted the importance of promoting a sustainable food cold chain. Cold chain technology is in high demand worldwide and is expected to continue growing in the future. However, the UN's report points out that there is a limited understanding of what constitutes an economically, environmentally, and socially sustainable food cold chain system. Previous initiatives have primarily focused on specific components within the cold chain, such as replacing refrigerants or improving energy efficiency to reduce electricity bills. In response to this, the United Nations is calling for a systemic change:

A wider systems approach is needed that adds focus on other core functions and cross-sectoral activities in the food cold chain that contribute to the sustainability and resilience of the agri-food system.

Let us delve into the significance of sustainable food cold chains and explore how new technologies can contribute to building a better food system.

Benefits of the food cold chain to our society

The cold chain refers to a continuous, temperature-controlled supply chain designed to maintain the quality, freshness, and nutrition of temperature-sensitive products throughout their entire journey, from production to consumption. It involves the storage, transportation, and distribution of temperature-sensitive products. When it comes to food, anything that needs refrigeration has likely traveled through the food cold chain.

From the consumer's point of view, the food cold chain offers a significantly wider variety of products to choose from. Under the influence of globalization, temperature-sensitive products such as meat and seafood can now travel across the world, thanks to the extended shelf life provided by the cold chain. It is now effortless for us to buy steaks or mangoes produced on the other side of the planet.

The food cold chain also promotes public health. Maintaining proper temperature control is essential for ensuring food safety and minimizing the risk of foodborne illnesses. Cold chains help prevent the proliferation of harmful bacteria and pathogens in perishable food items, protecting consumer health. By adhering to stringent temperature regulations and guidelines, cold chains contribute to safer food consumption practices and reduce the occurrence of food-borne diseases.

Furthermore, the cold chain aids in food resource management. The extended shelf life helps preserve food and beverage resources. Many agricultural products deteriorate at the same rate in one hour at a high temperature of 25°C as they do in one week at a low temperature of 1°C. The food cold chain enables products to remain in a sellable condition for a longer duration, reducing the need for frequent restocking and minimizing waste due to expiration and degradation.

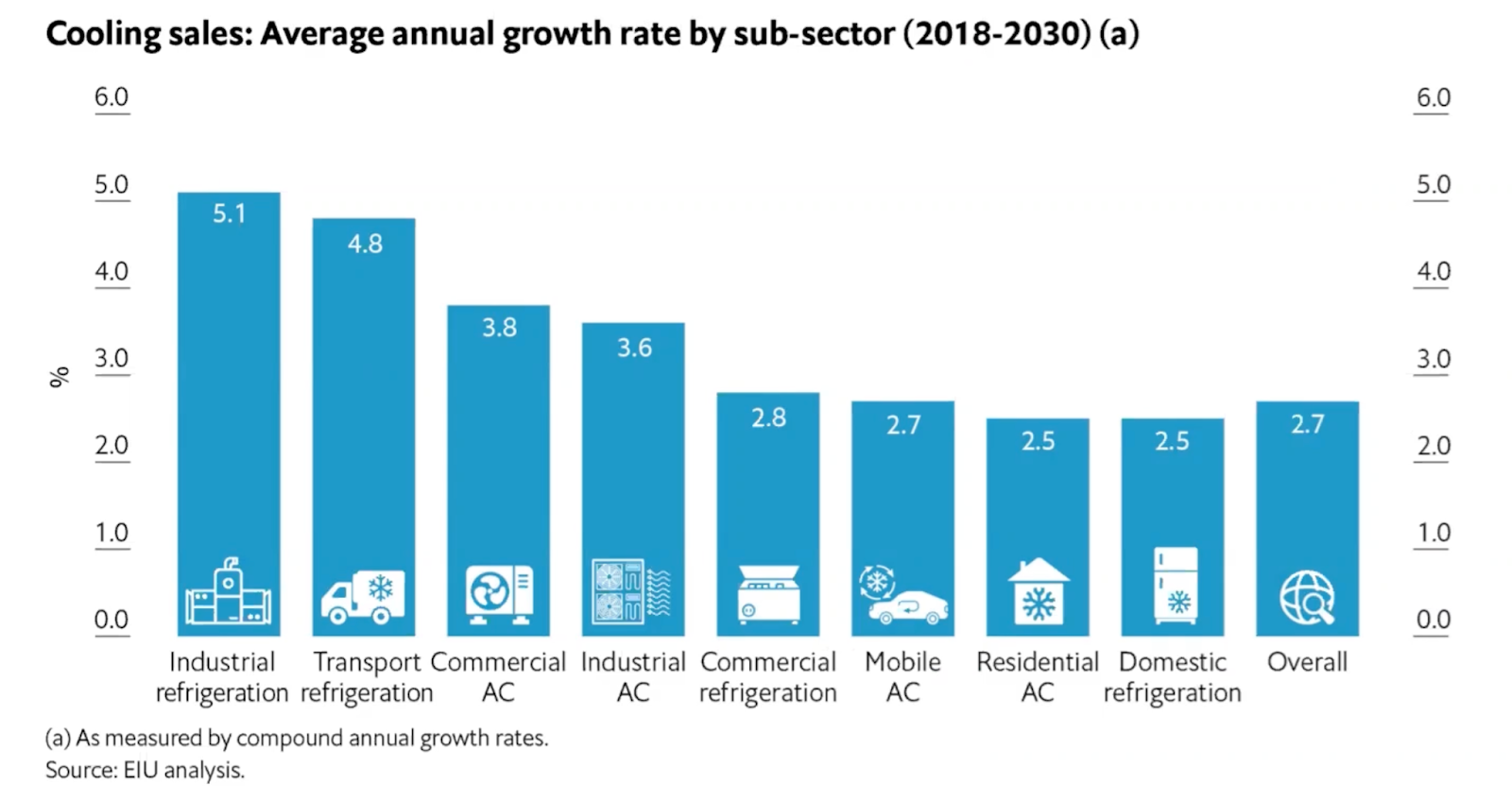

With all the benefits, the need for food cold chains and refrigeration is set to increase in the future. According to the Economist Intelligence Unit, the average annual growth rates of industrial refrigeration and transport refrigeration between 2018 and 2030 are expected to be 5.1% and 4.8%, respectively, surpassing other categories in the cooling industry. However, these benefits do come at a cost.

Climate change and the food cold chain

Currently, the food cold chain is responsible for 4% of global GHG emissions, including emissions from cold chain technologies and food loss and waste due to a lack of refrigeration. This may seem small, but it is not. It is equal to the climate change contribution of the entire continent of Africa! The GHG emissions from the food cold chain can be divided into three main categories:

(1) Energy consumption for refrigeration

Most refrigeration equipment requires electricity to operate, similar to domestic refrigerators at home. A study found that refrigeration in supermarkets accounts for 4% of total electricity consumption in developed countries. In addition to on-grid appliances primarily used for storage, temperature-controlled transportation within the cold chain also consumes fossil fuels from vehicles. Researchers have found that refrigeration contributes up to 40% of total emissions from temperature-controlled trucks.

(2) Refrigerant leakage

Another significant source of emissions is refrigerants. Many of the refrigerants used today have a high global warming potential, meaning that they more effectively contribute to global warming than carbon dioxide. Some refrigerants can be hundreds or even thousands of times more potent than carbon dioxide. These gases leak into the atmosphere through daily use, maintenance, and inappropriate disposal. Studies suggest that refrigerants used in cold chain transport account for 4% of the total global warming impact of moving all freight (including non-refrigerated transport). The leakage also leads to lower cooling performance, causing an increase in energy consumption to compensate.

(3) Food loss and waste due to a lack of refrigeration

Food supplied along the cold chain is vulnerable to ambient temperature. There is always a risk of deterioration due to accidents or mishandling. Spoiled food cannot be sold or served, resulting in the wastage of all the materials and energy used in its manufacturing and transportation, including the aforementioned emissions. Therefore, ensuring a reliable food cold chain is crucial for making our food system sustainable. It requires striking a balance between adequate refrigeration and minimizing its environmental footprint.

Considering the growing demand and environmental costs, the United Nations emphasizes the importance of promoting a sustainable food cold chain. In developed countries, emissions from cold chain equipment are already significant. A sustainable cold chain with minimal environmental impact is critical to saving the planet. On the other hand, in developing countries that already face energy insecurity, an energy-efficient cold chain can prevent adding pressure to the grid.

Pioneers in sustainable food cold chains

While researchers are still in the process of defining what a sustainable cold food chain should entail, various companies have been working on innovative solutions to address greenhouse gas (GHG) emissions.

For instance, Ecozen and ColdHubs have developed solar-powered walk-in cold rooms designed for storing perishable food items in off-grid areas. These systems can be deployed on farmlands with limited access to electricity, enabling farmers to preserve their produce and minimize post-harvest losses.

In the transportation sector, Thermo King offers a range of sustainable solutions, including hybrid and electric-powered refrigeration units. These solutions help reduce emissions and enhance fuel efficiency within the cold chain logistics sector.

Figor has developed a device that is placed in temperature-controlled storage or trucks to track key data, including the location, humidity, and temperature of highly perishable products. This data plays a crucial role in reducing post-harvest losses within the supply chain.

On the other hand, Relocalize takes a different approach by focusing on eliminating unnecessary steps in the supply chain. We believe that sustainability can be achieved by streamlining the supply chain and removing redundant processes.

What is better if the emission source is not there in the first place?

We start with the world's first food micro-factory, which is producing packaged ice in Florida. By freezing ice locally at the supermarket distribution center, we eliminate the need for upstream cold chain transportation and storage. This means there will be no energy consumption or GHG emissions from the long-haul delivery between the manufacturing plant and distribution center. For instance, we eliminate up to 90% of transportation emissions along the food cold chain.

The short food cold chain also mitigates the risk of deterioration during transportation. Every ice cube produced is immediately shipped to the retail location, supplying local communities on-demand. The logistics for storage and loading are minimal. Together, these efforts help reduce food waste along the supply chain.

In addition to the environmental gains, retailers can benefit from a drop in operational costs resulting from a streamlined food cold chain. Cost savings from distributors, drivers, and warehouses provide an incentive for switching to a more sustainable operation. Furthermore, the short supply chain ensures a more consistent restock, facilitating ongoing sales.

A wide range of food products depend on the food cold chain. While our system may not be suitable for primary food production like seafood and meat, it offers new insights into secondary food manufacturing, which accounts for 60% of all food in the U.S. Moreover, Relocalize’s food system is easy to set up and does not require retailers or customers to make significant adaptations, making it capable of creating a substantial impact.

We believe there is much more for us to explore regarding how hyper-local food manufacturing can promote a sustainable food cold chain. Our goal is to promote a system change in our food chain, making food fresher, greener, and better. Contact us if you are interested in fostering a sustainable food cold chain!